- Home >

- Testing >

- Testing and Evaluation >

- Laboratories and Facilities >

- Holloman High Speed Test Track (HHSTT)

Holloman High Speed Test Track (HHSTT)

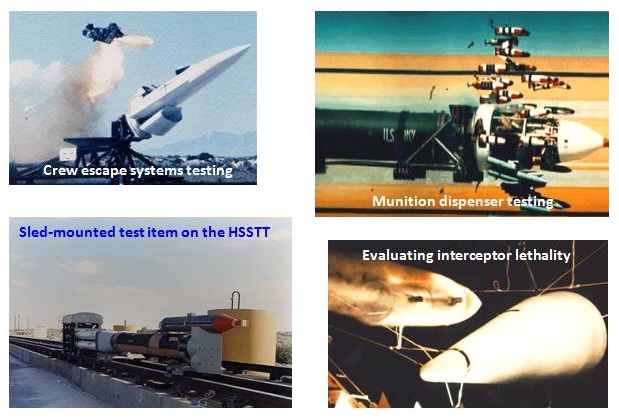

The Holloman High Speed Test Track is a rocket test and aerospace test facility which provides an efficient and safe means of testing customer test items while minimizing risks and reducing cost for a wide variety of test hardware in a near operational environment.

Specific advantages are: the test items are recovered for post-run analysis; the sled provides sustained linear and dynamic acceleration and velocity with superimposed, tailored vibration; and the sled track provides extremely accurate test article positioning and time correlation. Repeated tests of the same test item provide an independent evaluation of modifications made during a development program.

The Holloman High Speed Test Track is the longest (50,788 feet) and most precisely aligned and instrumented facility of its kind in the world. The track is used to simulate selected trajectories of aircraft and missiles under stringent conditions. Sled speeds up to 7,000 ft/sec are routine, while speeds above 8,900 ft/sec have been demonstrated. Depending on mission needs, sled weights range from 100 to 30,000 pounds; however, heavier sleds can be operated as required. Also, depending on payload size, accelerations above 200 g's have been demonstrated.

The Holloman High Speed Test Track is organized as a squadron under the 46th Test Group, a tenant organization on Hollman AFB, NM. It is physically located near the eastern boundary of WSMR, virtually unaffected by environmental encroachment problems. While operated primarily for the needs of the Air Force Materiel Command, its test capabilities are also avilable for other Government agencies and their respective contractors.

HIGH SPEED TEST TRACK (HSTT) TEST CAPABILITIES:

Lethality Testing: Missiles, warheads, bombs, hit sensors, and hit-to-kill interceptors have been subjected to impact testing against stationary inert and live munition targets at speeds ranging from 3,000 to 8,000 ft/sec. To prevent sled debris contamination on a target, the sled payload or test item can be released from the sled just prior to impacting the target by means of a "pull-down" facility.

Explosive Blast Effects Testing: Blast effects on moving sleds are conducted with high-explosive detonations. The objective of blast testing on the track is the simulation of an explosive blast shock wave intercept on full-scale reentry vehicles and on components of aircraft, missiles, and aerospace systems during supersonic and hypersonic flight.

Environmental Erosion Testing: Rain, ice/hail, dust and other particle erosion testing have been conducted at the Test Track. Rain erosion testing is conducted to study the erosive effects of extended supersonic or hypersonic flight through rain clouds on material samples, fuzes, sensors, seeker heads, electro-optical windows, radomes, shrouds, inlet diffusers, and other components of weapons and aerospace systems. The simulation of a reentry vehicle or ICBM entering a dust or pebble environment caused by a nuclear blast have also been conducted at supersonic and hypersonic speeds. Recoverable test samples from subsonic test speeds up to 7,400 ft/sec are routine. A single test item can be mounted to existing monorail test sleds and propelled through a simulated rain field. Multiple samples on special 7-cone test fixtures or wedges attached to a monorail sled have been conducted. A standard simulated rain rate of 2.5 inches/hour through a length of 6,000 feet is also routine. Shorter lengths of simulated rain fields can be provided. Lighter rain rates have been charted and provided in accordance with special customer requirements. A 2000 foot ballistic test range adjacent to the Test Track with simulated rain rates up to 25 inches per hour has been used for artillery fuze testing.

Hypersonic Environmental Testing: Structural materials and ablative or refractory coatings are tested to evaluate aerothermal effects in a hypersonic environment. Test articles and samples included heatshields, radome covers, missile and interceptor nose cones, and shrouds. Test samples can be recovered after a sled test for post-test analysis and evaluation.

Dispenser Systems Testing: This category of testing encompasses the dispensing or launching of rocket-powered weapons, the dissemination of bomblets, flechettes, submunitions, and the dissemination of power-like substances from payload carriers mounted on a test sled in a dynamic environment. The dispensing of radome covers or shrouds protecting seekers or electro-optical windows have also been demonstrated at supersonic and hypersonic test speeds.